-

Pathways to reduce emissions

Our planet matters. Elon Musk’s plans aside, it’s the only one we have. Right now, our failure to take climate change sufficiently seriously is compromising the ability of the world’s population to live well and to prosper in the years to come. As lean practitioners we have the ability to impact our planet for good. With…

-

Seeing and Understanding the Work in Product and Process Development

The biggest benefit of making the work visible – the conversations and interactions it facilitates. The ensuing dialogue about the plan facilitates mutual understanding amongst the different functions involved about how their work fits together to deliver customer value. This isn’t about just understanding the plan, but understanding each other and the impact of decisions and…

-

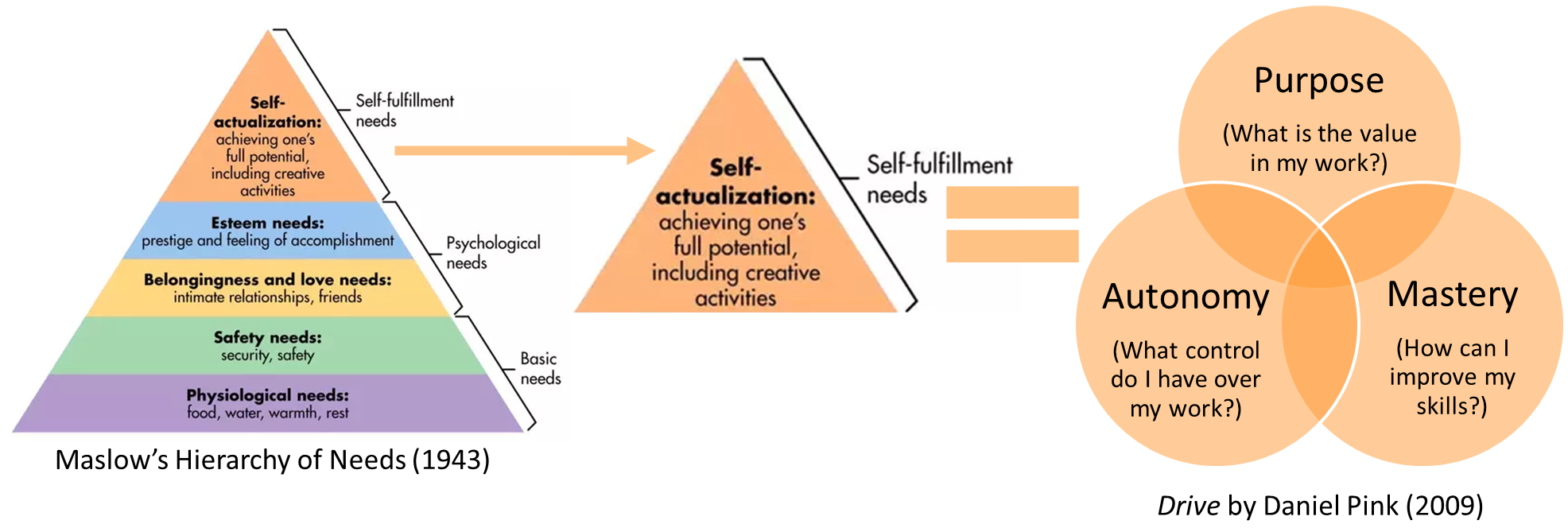

Coach’s Corner: How To Put People First Using Lean Practices

Not only will putting people first lead to better performance, but it will also make your organization a more attractive employer. People want good jobs doing meaningful work where they can thrive, which you can help them achieve when you deliberately put people first using lean practices with supportive leadership behaviors.

-

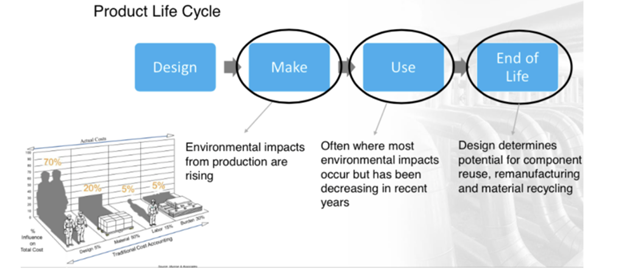

Coach’s Corner: Designing the Entire Value Stream From Concept to Product End Life

When people think about the environmental impact of the products they use, most think about the implications of their use and their disposal at the end of life. As design improvements continue to reduce emissions during the use phase, the importance of reducing the emissions during production becomes more evident. One-third of emissions come from making products. Designing your value stream to have a lower environmental impact in production could reduce your costs, lower your carbon footprint, and influence future…

-

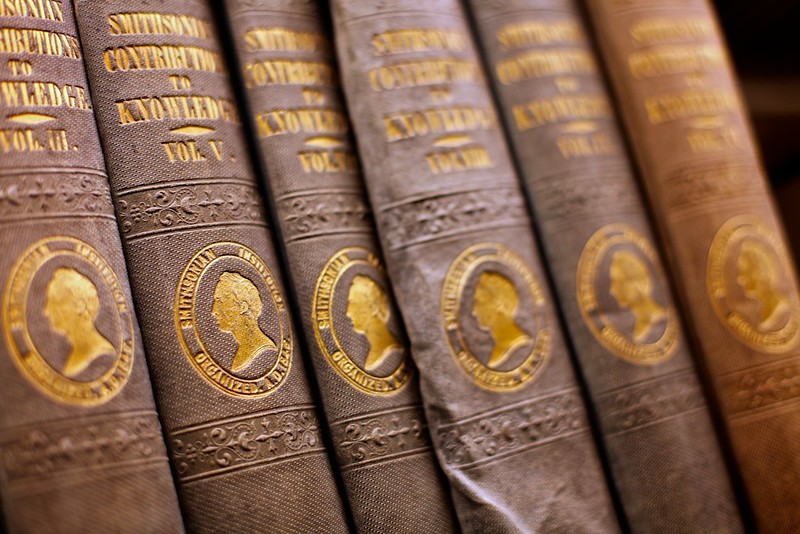

Coach’s Corner: How to Design a Knowledge-Sharing System

Designing knowledge-sharing practices that will allow people to get the necessary knowledge at the right time ensures that your team reuses the knowledge your organization has already created. Critically, deploying such a system frees team members to focus their time and energy toward creating new organizational knowledge. Continuously reusing and creating new organizational knowledge sets the foundation to develop new innovative products providing a competitive advantage consistently.

-

Why it’s Better to Focus on Value, Not Waste

Many organizations primarily focus their lean efforts on eliminating waste. While nobody wants waste in their value stream, it would be better to focus on increasing value. Emphasizing value creation reduces the risk that you will unintentionally remove value-creating activities while searching for waste. Emphasizing value creation also ensures that you deliver more value through…

-

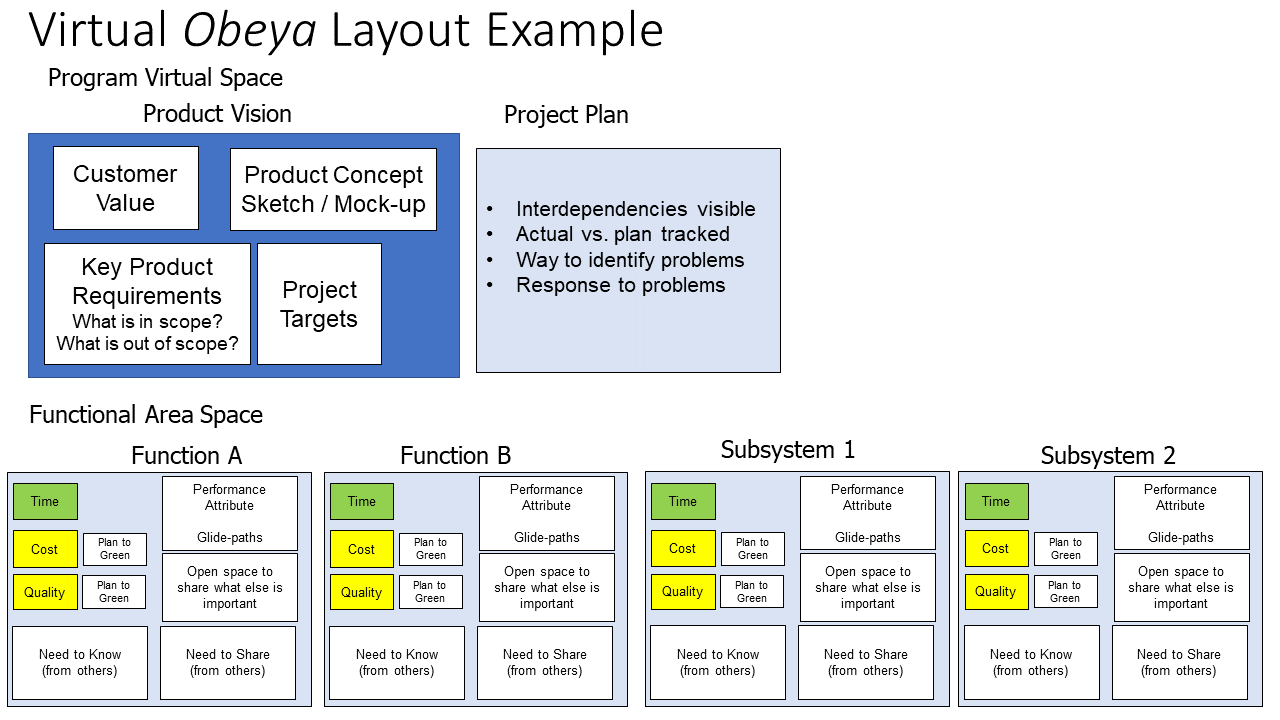

How a virtual obeya can enable effective teamwork

With an obeya, we are trying to create conditions for teams to effectively work together to make decisions and solve problems… understanding the work visually. This shared understanding of the work needs to include how everyone’s work fits together including interdependencies.

-

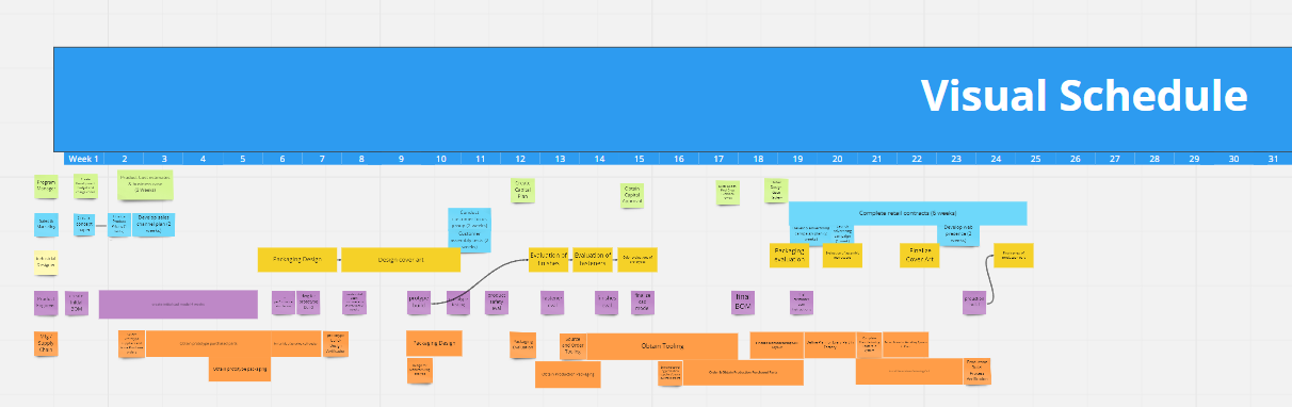

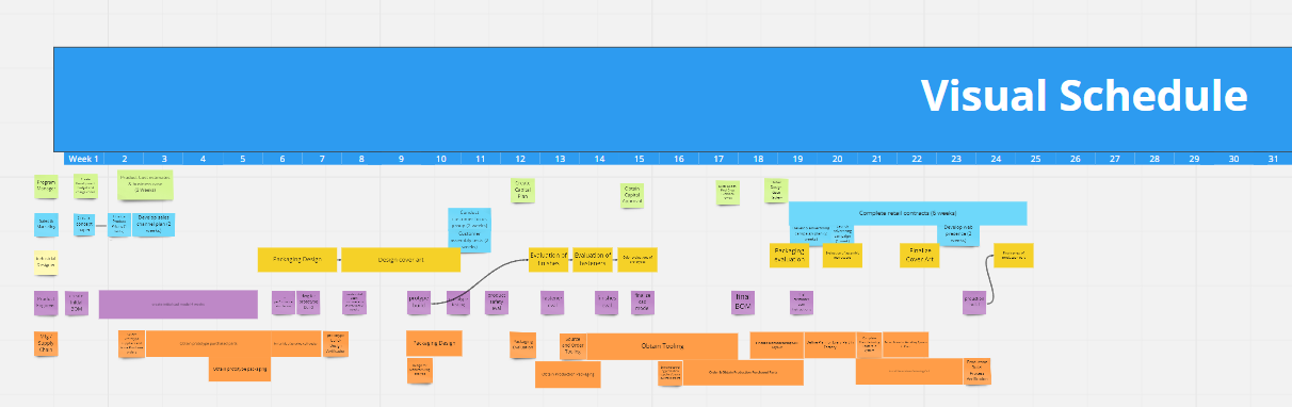

The Value of A Visual Schedule is Developing Shared Understanding

Collaboratively creating a schedule gives individuals the autonomy they need to control what they are working on. It also helps connect to purpose with how their individual work fits into the overall development plan. Mastery is focused on skill development, which usually isn’t part of schedule development but is a piece of the puzzle you…

-

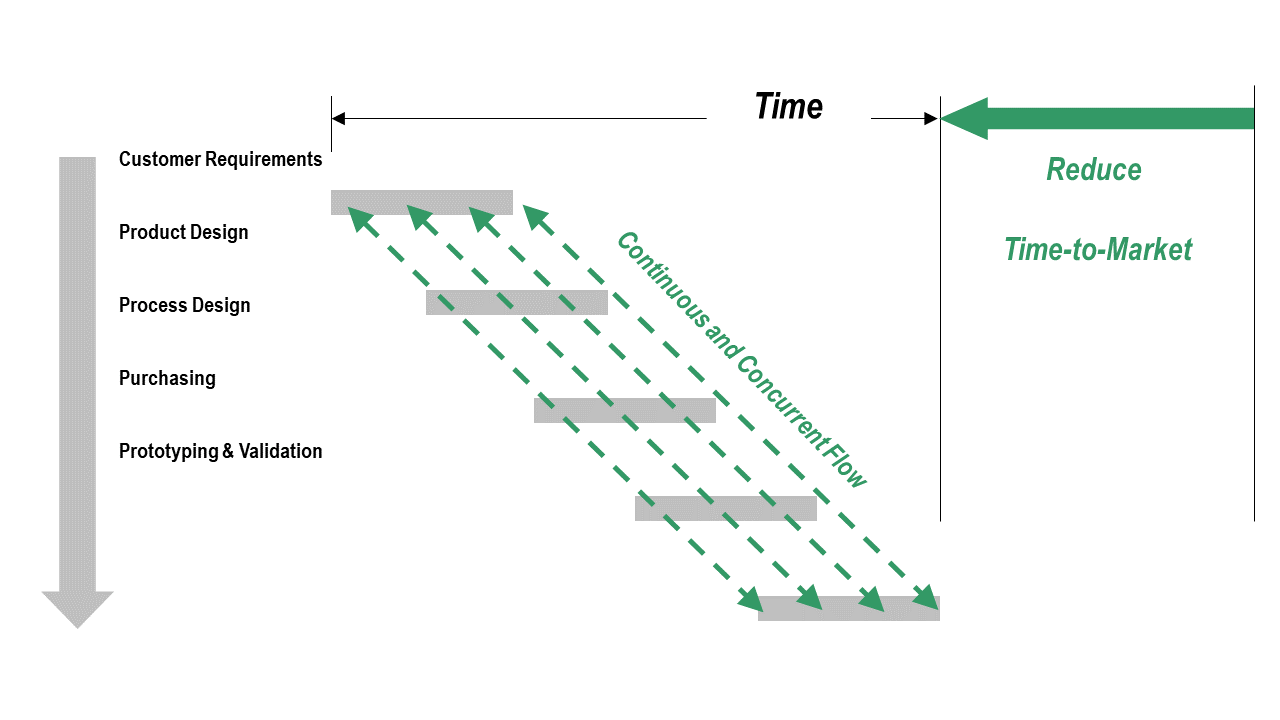

The Dark Side of Concurrent Engineering

Avoiding the “dark side” begins with understanding the work and interdependencies to enable downstream partners to provide inputs at the right times to incorporate their knowledge earlier in the process. This isn’t just inviting people to participate in meetings earlier, but rather understanding the work together and what information is relevant at the right time and then…

-

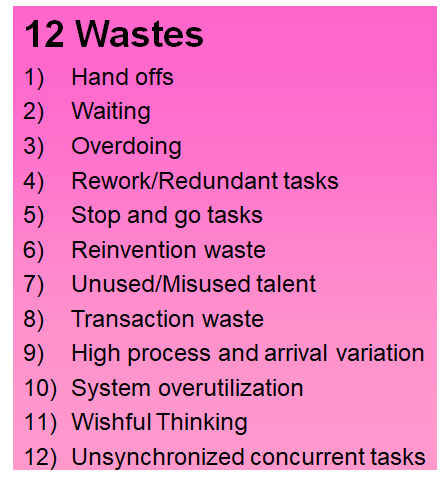

12 Wastes of Product & Process Development

The wastes found in manufacturing have been well documented over the years. As we move upstream into product development, the environment is clearly different, but waste is unfortunately just as prevalent. It is harder to “see” as it morphs itself into different categories than those found in the factory. Based on the works of Jim…